Switch from Maximo to L2L

When support ends, your operational risk rises. If you are a Maximo user evaluating alternative solutions, don't get left behind.

L2L is purpose-built for manufacturers, fast to deploy and easy to use, with results you can see in weeks.

(... and lots of ex-Maximo users love us)

Don't get left behind

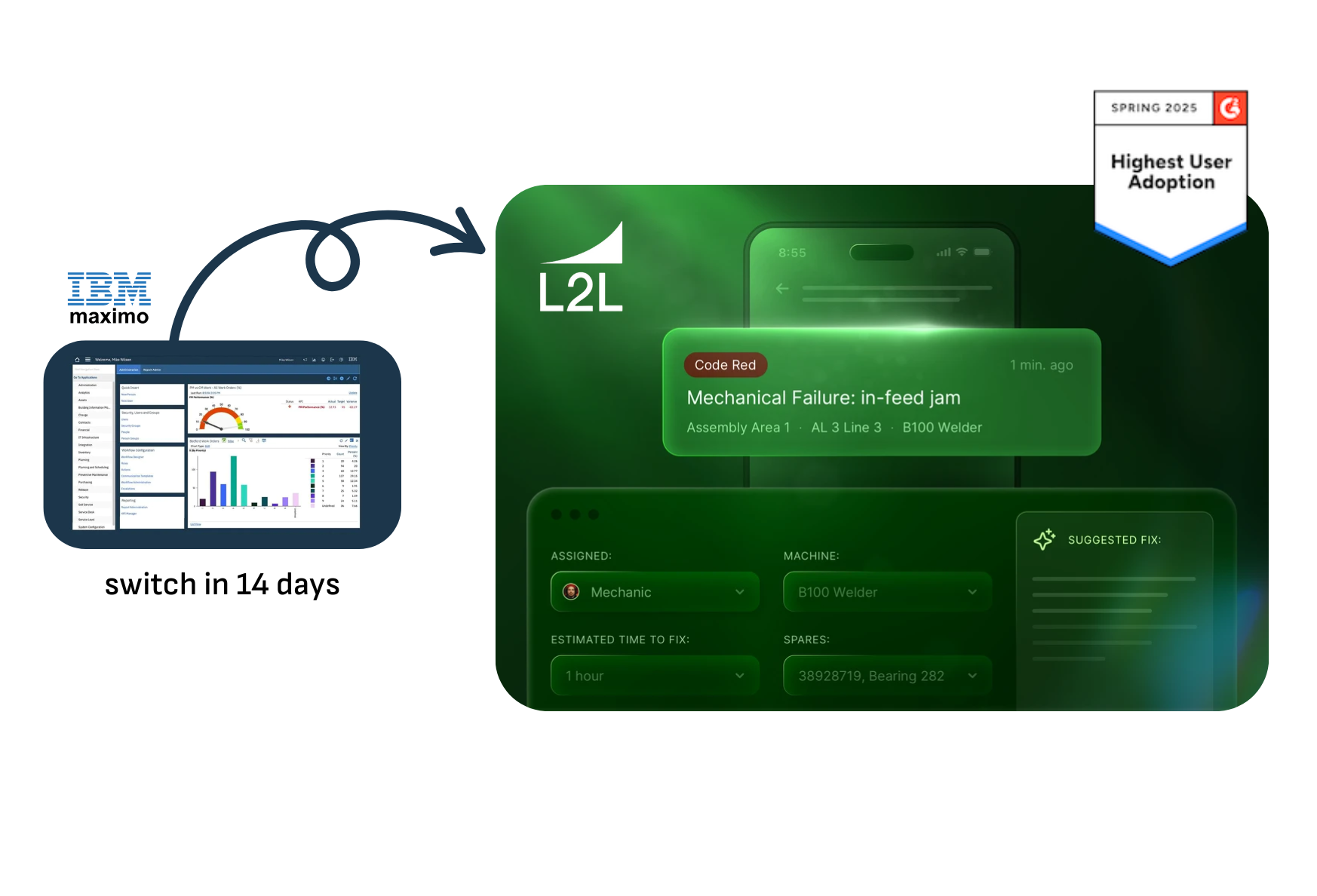

Many Maximo users are seeking a more agile, tailored solution and a true upgrade in functionality and user experience, not just a replacement.

Common questions Maximo users are asking and how L2L can help:

1. What exactly is happening with IBM Maximo?

IBM Maximo version 7.6.1 is reaching its End of Support (EOS) on September 30, 2025.

This means IBM will no longer provide standard support, including security patches, bug fixes, and updates for this specific version.

Ignoring this means your system will be vulnerable to security threats and lack critical updates.

2. What are the risks of staying on Maximo 7.6.1 after September 30, 2025?

Continuing to use Maximo 7.6.1 after the EOS date exposes your organization to significant risks, including:

- Security vulnerabilities: Without security updates, your system becomes more susceptible to cyberattacks.

- Compliance issues: Depending on your industry and regulations, running unsupported software can lead to compliance violations.

- Lack of bug fixes: Any software issues you encounter will not be addressed by IBM.

- Limited support: You will have limited or no access to IBM's technical support for your Maximo 7.6.1 system.

3. Is migrating to the Maximo Application Suite (MAS 8) my only option?

While IBM is encouraging users to migrate to MAS 8, it's not your only option.

Many organizations are exploring alternative Enterprise Asset Management (EAM) solutions that offer a more flexible, cost-effective, and tailored approach.

L2L is a strong alternative that can provide a seamless transition and broader scope of functionality.

4. Why should I consider switching to L2L instead of migrating to MAS 8?

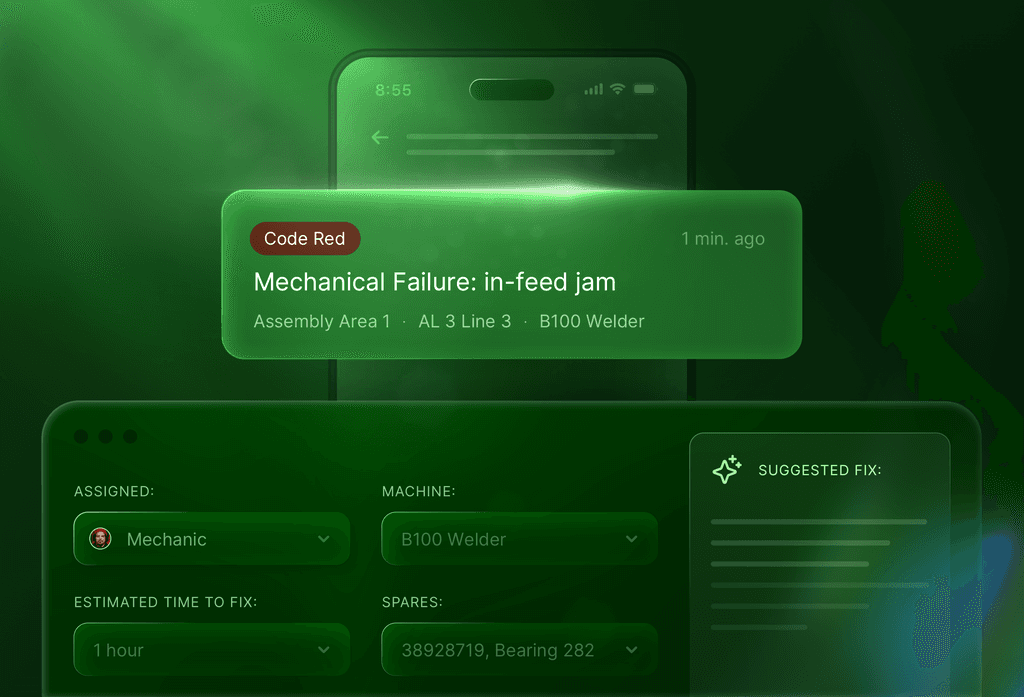

L2L offers a comprehensive smart manufacturing solution built to eliminate downtime.

- More than just assets: Includes robust Asset Management, Workflows, Advanced Planning & Scheduling, MES, CMMS, Manufacturing Intelligence, and Predictive Maintenance.

- User-friendly: Intuitive interface for better frontline adoption.

- Flexible and scalable: Adapts to your needs and grows with you. Choose what use case and module to start with.

- Competitive pricing: Offers strong value. Whatever IBM quotes you, expect L2L to be half the cost.

- Tailored to you: Focused on your specific needs. With your personal success manager and implementation team.

5. Will transitioning to L2L disrupt my operations?

Your plant is in good hands! Our implementation experts make switching from Maximo smooth. Your tailored L2L solution will be up and running within 14 days - without any disruption to your operations.

|

|

|

| Asset management | ||

| Workflows | ||

| Advanced planning and scheduling | ||

|

MES - Manufacturing execution and procedures

|

||

|

CMMS - Maintenance and task management

|

||

|

Manufacturing Intelligence - Advanced cross-site dashboards

|

||

|

Predictive maintenance and analytics

|

||

| AI-powered spare parts and suggestions | ||

| Visual guides for technicians | ||

| Easy setup and admin | ||

| Low cost of ownership | ||

| Get started in 14 days |

Trusted by global manufacturing leaders

Why L2L is the smart choice

for Maximo users like you

Why L2L is the superior alternative to the complexities of migrating to MAS 8.

Feature-rich & future-ready

L2L provides a comprehensive suite of tools, including:

- Asset Management

- Streamlined Workflows

- Advanced Planning & Scheduling

- Integrated MES

- Powerful CMMS

- Advanced Manufacturing Intelligence

- Predictive Maintenance

Up and running faster

Our smooth implementation gets you up and running quickly, realizing time-to-value sooner.

- Rapid deployment and implementation process completed in just 14 days.

- No disruption to your operations

- Intuitive interface made for frontline teams.

- Quick user adoption and improved productivity

.jpg)

Clear ROI

Superior value, lower cost.

- We always offer a more competitive price than what IBM may quote you.

- Boost productivity for your team.

- We get manufacturing. Our team of experts will guide you to success.

- Avoid the hidden costs of outdated systems.

The switch takes 14 days

Our team of experts (they all have 10+ years in manufacturing) will take care of the transition for you. You'll be up and running with L2L within 2 weeks.

No disruptions to your operations.

Why companies switch to L2L

Increasing throughout

“We have achieved real-time visibility of critical metrics and enabled fast and accurate responses, increasing efficiency throughout our plants. L2L is a strategic partner and plays a big role as we strive for operational excellence.”

.png?width=500&height=500&name=ADAC%20(4).png)

Eliminates downtime

“Everything we need to improve efficiency, reduce unplanned downtime, drive waste out of the process, and react faster to change.”

Fewer quality issues

“There’s not as much downtime. If I have a quality issue, it gets fixed faster because I can make a Dispatch in L2L and the technician knows exactly what’s going on before they get to me. I thought it would take months to figure it all out, but I felt comfortable using it after a couple of days.”

Brings everyone together

"It is really exciting - L2L leads our startup meetings now. It helps us have good visibility. L2L helps us bring everyone together."

Mindblowing connectivity

”I've been in this business for 32 years and I never would have imaged the level of connectivity. It just blows my mind Maintainers are aware if an issue has happened before and can also share how to fix it with others on the line."

Real smart manufacturing

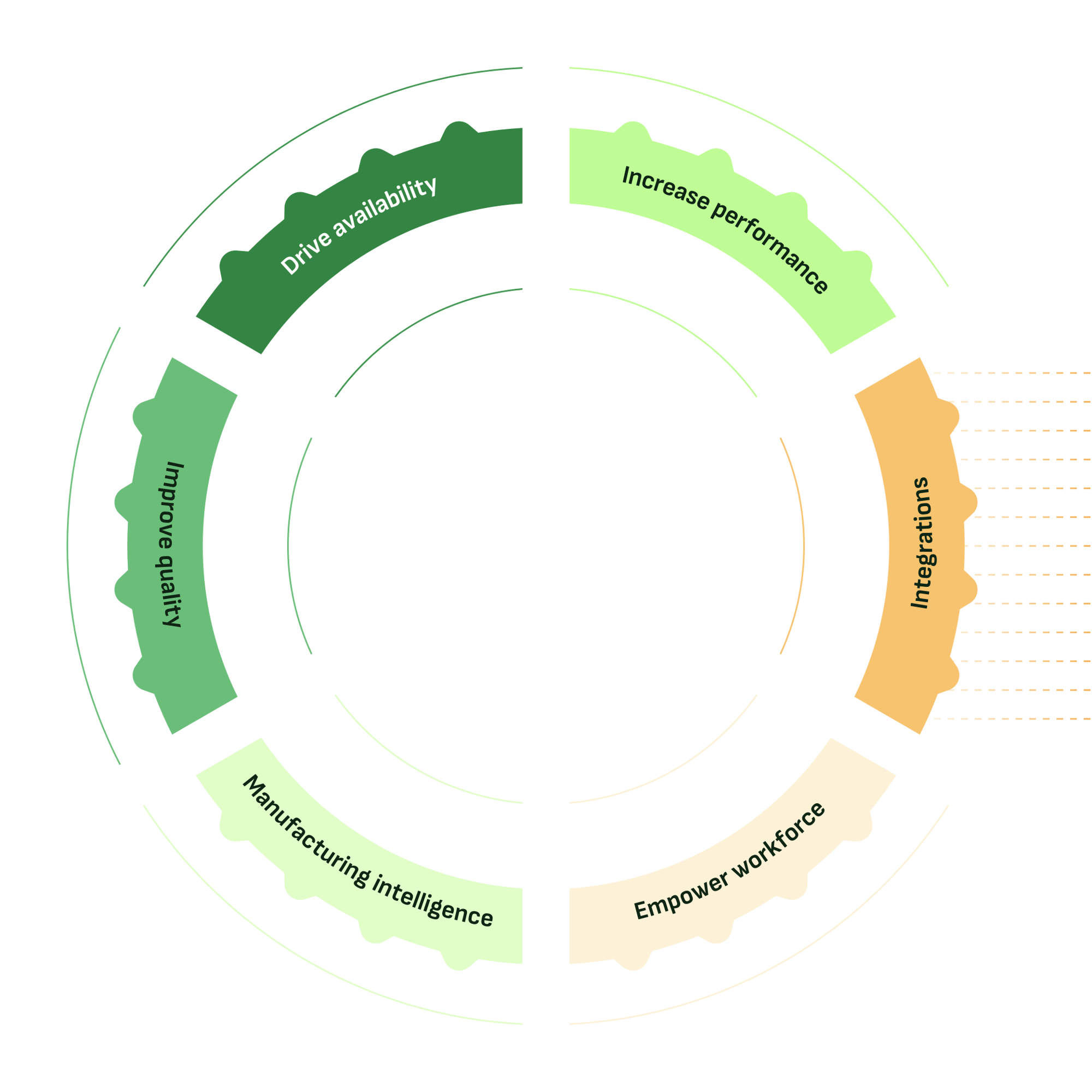

Continuously improve all of your manufacturing processes.

L2L is the all-in-one smart manufacturing platform that gives you better insights before, during, and after every shift.