Manufacturers rely on Overall Equipment Effectiveness (OEE) to understand how well their production processes are running and where they lose productivity. OEE offers a precise, quantifiable measure of plant performance by breaking down Availability, Performance, and Quality (APQ).

These factors directly impact your organization’s bottom line. Having accurate APQ data allows you to pinpoint issues like downtime, slow cycle times, and defects so you can focus on maximizing efficiency and profitability.

Connected workforce platforms like L2L offer mobile-friendly OEE dashboards.

Let’s take a closer look at the basics of the OEE calculation, how to leverage OEE to improve productivity, and how connected technology makes tracking OEE easier.

OEE formula

The most accurate way to calculate OEE is to multiply Availability, Performance, and Quality as discussed above.

Here’s a quick breakdown of each factor:

- Availability: The percentage of time equipment is ready for production out of its planned production time.

- Performance: How quickly production is running.

- Quality: The percentage of good-quality parts produced.

Therefore, the best OEE calculation formula looks something like this:

Let’s see what this looks like in a real-life production environment.

Real-life OEE calculation example

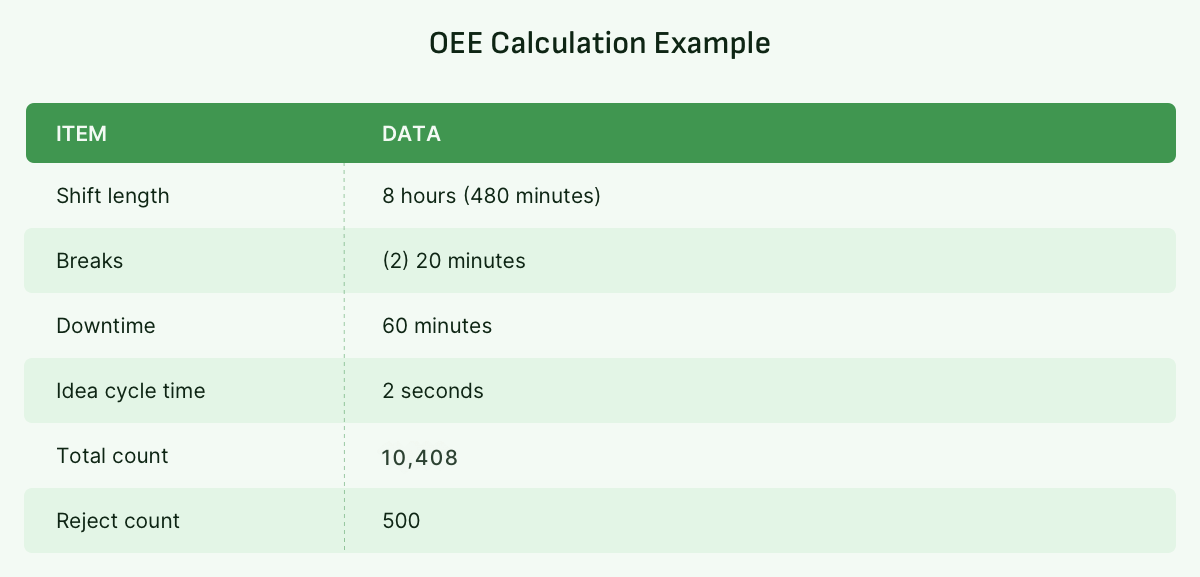

For instance, a line packaging bottles into cartons may be scheduled to run eight hours per shift, taking two seconds to fill each carton.

However, due to frequent line stoppages, the line incurs 60 minutes of unplanned downtime during this shift—not counting the two 20-minute breaks scheduled during the shift.

Additionally, 500 of the 10,408 cartons produced are defective.

Plugging in the numbers from the chart above, we can easily calculate OEE for that shift. We’ll break down how to do that below.

OEE availability calculation

Availability measures the percentage of planned production time that equipment is actually running. It accounts for downtime losses due to equipment failures, changeovers, or other stoppages.

The formula for Availability is:

- Planned Production Time is the total time the equipment is scheduled to operate.

- Run Time is the actual operating time after subtracting downtime losses.

Using the packaging plant example, we find that:

- Planned Production Time = 440 minutes

- Downtime Losses = 60 minutes

Run Time = 440 - 60 = 380 minutes

Availability: (380 / 440) x 100 = 86%

Availability losses generally fall into two categories surrounding line stoppages:

- Unplanned Stops: Breakdowns, material shortages, or operator issues.

- Planned Stops: Changeovers, maintenance, or cleaning.

Reducing downtime, whether planned or unplanned, is key to improving Availability and overall OEE.

OEE performance calculation

Performance measures how efficiently equipment is running. Let’s see what this looks like in a real-life production environment.

The formula for Performance is:

- Ideal Cycle Time indicates the highest possible production rate based on the ideal cycle time.

- Actual Cycle Time indicates the rate at which good units are produced.

In our packaging plant example, we can conclude that:

- Run Time = 420 minutes

- Ideal Cycle Time = 2 seconds per carton

- Theoretical Maximum Output = (380 x 60) / 2 = 11,400 cartons

Actual Output = 10,408 cartons

Performance: (10,408 / 11,400) x 100 = 91.3%

Performance losses, including minor stoppages and slow equipment operation, can negatively impact OEE. That’s why you need to monitor machine performance with modern analytics tools.

OEE quality calculation

Quality measures the percentage of good products produced out of the total products made. It accounts for defects and rework, which reduce overall efficiency.

The formula for Quality is:

- Number of Good Products: Total products made minus defective products.

- Total Products Made: All units produced, including defective ones.

Start by identifying the number of good-quality cartons produced:

- Total Products Made = 10,408 cartons

- Defective Products = 500 cartons

- Number of Good Products = 10,408 - 500 = 9,908 cartons

Using the numbers above, this is how we’d calculate Quality for OEE:

Quality: (9,908 / 10,405) x 100 = 94.8%

A 94.8% score means that more than 5% of parts were defective and needed to be scrapped or reworked.

How to calculate OEE

Now that we’ve calculated our APQ percentages, it’s time to plug in our numbers for our official OEE score:

OEE (APQ) = 86% × 91.3% × 94.8%

OEE = 74.43%

A 74.43% OEE suggests room for improvement, with the biggest losses coming from Availability (downtime) and Quality (defects). In this scenario, the plant should focus on solving for downtime—planned and unplanned—as well as reducing their 5.2% defect rate.

Compared to industry benchmarks, 74.43% OEE is on the “average” side but nowhere near “world-class.” Check out the pie charts below for a rough estimate of OEE industry standards.

Remember that OEE helps you identify losses and process inefficiencies but not necessarily their root causes. To fully understand where your losses are coming from, you’ll need to analyze your APQ calculations using a modern Manufacturing Execution System (MES).

Benefits of tracking and improving OEE

Tracking Overall Equipment Effectiveness provides a clear, data-driven view of how efficiently a plant is running. OEE helps pinpoint specific problem areas, whether it’s frequent equipment breakdowns, slow cycle times, or high defect rates, so you can spot and eliminate obstacles to productivity.

Beyond improving equipment efficiency, OEE tracking supports data-backed decision-making for maintenance schedules, capital investments, and process improvements. Plants that consistently monitor OEE can:

- Set realistic improvement goals

- Optimize production planning

- Reduce costs associated with waste and inefficiencies

Over time, small percentage increases in OEE can lead to significant gains in output and profitability. However, tracking OEE alone isn’t enough to maximize productivity. You must also monitor labor metrics. Measuring operator efficiency, idle time, and workforce utilization ensures that both machines and employees perform at their best.

Check out the video below to learn more about the manufacturing variables you should be tracking:

A plant can have high OEE, but if labor inefficiencies exist, overall productivity will still suffer.

Calculate and track OEE with connected workforce software

Using intuitive digital technologies and empowering frontline workers is key to improving OEE and driving operational excellence.

Solutions like connected workforce platforms do more than just track OEE. They help manufacturers act on the data in real time. Instead of relying on manual logs, these systems automatically capture machine performance, downtime events, and production trends, making it easier to spot inefficiencies and reduce unplanned stops.

They also improve collaboration and standardization across teams. Operators can log downtime reasons instantly, maintenance gets real-time alerts, and supervisors can track trends to drive continuous improvement.

Want to see how connected technology simplifies OEE calculation? We explain it in this short video.

The better your production data, the faster you can transform your manufacturing operations.

Schedule an L2L demo with our manufacturing experts to get started on your journey to optimal OEE—and productivity.

Revisions

Original version: 19 March 2025

Written by: Evelyn DuJack

Reviewed by: Eric Whitley

Please read our editorial process for more information

Related Posts

Subscribe to Our Blog

We won't spam you, we promise. Only informative stuff about manufacturing, that's all.