Table Of Contents

The manufacturing industry is going through some big changes. As analytics, sensors, robotics, cloud computing, and Industrial Internet of Things (IIoT) technology become cheaper and easier to implement, more and more manufacturers are forced to digitize their business and production processes to stay competitive in the market.

Join us as we discuss what digital transformation in the manufacturing industry looks like, what kind of advantages it brings, how manufacturers deal with implementation challenges, and lastly, what success looks like for these manufacturers.

What Is Digital Transformation in Manufacturing?

Digital Transformation (DT) refers to integrating digital systems and technologies into otherwise conventional processes. In manufacturing, there are limitless applications for DT to enhance production practices.

Some digital technologies that are leading the way in the industry include:

-

Machine Learning and Artificial Intelligence: Mimicking functions of human intelligence, artificial intelligence enables real-time data analytics, factory automation, and autonomous systems. Machine learning is a subset of artificial intelligence that allows machines to adapt to new data without human intervention.

-

Manufacturing Analytics: Using innovations like big data, machine learning, predictive analytics, and sensors, manufacturing analytics is a category of smart manufacturing technology that turns factory data into actionable insights.

-

Predictive Maintenance (PdM): PdM is an approach to plant maintenance that monitors and analyzes machine data in real time, predicting breakdowns before they occur.

-

Digital Twins: A digital twin is a virtual replica of a factory, system, or asset that functions as a digital counterpart for testing, simulation, and other experimental activities.

-

Robotics: Advancements in robotic technology, including AI-driven robots and cobots, enable manufacturers to automate repetitive tasks, maximize precision and accuracy, and increase productivity across the end-to-end production cycle.

-

Augmented and Virtual Reality: Augmented reality combines digitally generated content and real-world experiences via devices like smart glasses and VR headsets. Virtual reality uses computer-generated environments to simulate realistic experiences, typically through wearable technology.

-

Autonomous systems: Manufacturers use autonomous systems, which are networks of IP routing prefixes, to enable machines, systems, and processes to run autonomously.

Despite these state-of-the-art tools, digital transformation is not (or shouldn't be) so much a technology initiative as it is a business initiative. Ultimately, the goal is to drive overall performance improvement, efficiency, and quality. Naturally, driving improvements to these areas will lead to a significant gain to your bottom line.

While technology can be a tool to achieve these objectives, digitalization goes beyond just hardware. It transforms business practices to achieve and sustain objectives. It helps to pave the way to a continuous cycle of operational improvement. Digital transformation in manufacturing is a way to keep businesses ahead in an increasingly competitive market.

The Current State of Digital Transformation in the Manufacturing Industry

Here at L2L, we love data. The whole purpose of our connected workforce platform is to give manufacturers the data visibility they need to drive continuous improvements across their production floors.

At the beginning of 2023, we surveyed over 100 manufacturing leaders across Produce, Operations, IT, Engineering, and Management to glean insights on the state of digital transformation in manufacturing.

The data we collected revealed some important findings:

-

42% of respondents said they haven’t started a digital transformation journey.

-

Almost half of manufacturers don’t know if their competitors invest in digitalization.

-

Two-thirds of manufacturers believe their competitors are ahead of them in digital transformation.

-

Legacy technology and the lack of a clear path forward are cited as the biggest barriers to digital transformation.

-

Survey participants estimated that only half of frontline workers in their facilities were satisfied with their jobs.

-

38% of respondents expressed that connected worker technology is integral to their digital transformation strategies.

-

48% of respondents said that reduced costs are digital transformation’s greatest benefit.

For the complete overview of all data and questions we asked in the survey, take a look at this Digital Transformation Survey infographic below.

Let’s take a more in-depth look at specific sections outlined in the infographic above.

Benefits of Digital Transformation in Manufacturing

With all the talk about innovation and leaps in technology, you cannot help but have high expectations in terms of rewards. After all, every business initiative looks for a sound return on investment.

If the sheer joy of a futuristic plant has not won you over yet, think of these practical benefits that most manufacturers are expecting from their digital transformation journey.

Reduced costs

A recent Deloitte study shows that companies with higher levels of digital maturity reported higher net profit and revenue growth. In other words, an organization that has utilized DT for business benefit realized a notable increase in earnings compared to the industry average. The immediate advantages of technology are easily recognizable, such as efficiency and quality improvement. What comes later down the line are reduced costs and increased yield.

For instance, utilizing sensors to understand which machines are experiencing recurring issues, and which are hitting the bottom line the hardest, can give direction to workers’ improvement efforts and a relatively quick ROI. Perhaps efficiencies can be gained by installing robots and automation to solve targeted problems, augmenting production throughput by allowing for autonomous operations.

On top of that, meticulous AI algorithms can ensure that the system consistently produces high-quality products. These factors translate into reduced unit costs while maintaining sustainable production capacities.

Data visibility

While traditional computers are capable of substantial data storage, their physical constraints restrict sharing capabilities. Moving towards a digital approach opens up channels for data to be visible with virtually limitless storage space in the cloud.

By making data both visible and accessible in real-time, it allows for the broader workforce on the plant floor (i.e. line operators, maintenance technicians, quality personnel, etc) to make more informed decisions and to more effectively collaborate toward a common objective — production performance. After all, when production wins, everyone wins.

Data visibility can sound like an unremarkable step, but it translates to reducing redundant work, increasing data accuracy, and identifying the right improvement opportunities that will impact the bottom line.

Improved process and equipment reliability

Unplanned downtime is estimated to cost manufacturers $50 billion annually. This hefty price tag deserves special attention, and digital technology may have the answer in the form of predictive maintenance.

Predictive maintenance is a strategy that aims to increase reliability by taking corrective action even before a breakdown event occurs. It employs sensors, measuring devices, and wireless communication devices that gather information about an equipment's operating conditions. Specialized software performs analyses using real-time data to come up with maintenance alerts and recommendations. This strategy ensures that assets are well-maintained, without wasting your internal resources on unnecessary maintenance work.

Greater flexibility

A digital mindset reduces a company's dependence on physical limitations. A pertinent example of how digital transformation allows greater flexibility is through software offered as a service.

Software products used to be exclusive to companies of a particular size or type of operation. On-demand software did not give enough room for expansion or upgrades. Cloud-based software, on the other hand, offers a more customizable experience. Products are typically available as subscription services that can adapt as the company shifts priorities or expands in size.

Improved efficiency

Having the right tools increases productivity while reducing work input. Moving from a tedious and repetitive process to a digitally enabled system can remove a lot of the unessential waste in a company.

A smart factory, for example, demonstrates how digital transformation in manufacturing takes the fundamental roles of a conventional plant and maximizes performance using modern technology.

Imagine a facility continuously gathering and analyzing data to make processes better. A facility can earn efficiencies through resource optimization, defect elimination, and safety, all through DT.

Process standardization

While numerous manufacturing activities involve machines, many processes still require manual processing. These activities would include sorting out workflows, performing inspections, and even maintenance servicing. Implementing a digital solution offers a way to standardize existing habits.

For example, work order prioritization and the accomplishment of essential tasks can be automated and tracked through a mobile device. DT also paves the way for specialized software to simplify maintenance procedures. CMMS or EAM software, in particular, can program maintenance tasks to recur according to specified intervals or usage conditions.

Operational predictability

The manufacturing industry has always been a competitive space. The best companies strive to maintain a competitive advantage against other players. The same pattern is evident in the survey responses showing the manufacturers' awareness of their competitors investing in digital transformation.

What is also interesting is the perception that they are lagging in the DT journey compared to others. With digital transformation being the way of the future, it is apparent that manufacturers are thinking about picking up the pace to avoid being left behind.

Challenges Manufacturers Face Before and During the Digitization Process

The undeniable benefits of implementing digital transformation in manufacturing are a strong motivator for both management and operations teams. However, it is understandable that big changes come with some initial hesitation.

In the image below, you can see what manufacturing leaders perceive as top-tier challenges they will need to overcome before and during the digital transformation process.

-

No clear path. A clear framework sets the rest of the project in motion. Without a clear way forward, the success of any initiative is at risk. A smart manufacturing roadmap can be invaluable in understanding where you are and where to invest next for smart factory success.

-

Lack of funds. As with most projects, a DT initiative comes with an initial investment. The infrastructure required to digitize processes can be intimidating. Funding becomes a balance between finding cost-effective solutions and quantifying savings in the long run.

-

Legacy systems and technology. Manufacturers are prone to hang on to legacy systems. Migrating to a new system is a strenuous activity requiring a comprehensive change in management strategy. The process should cover everything from adjusting to new workflows to managing data transfers and delegating tasks.

-

Cybersecurity. DT allows for more automation and consequently more expansive ways of data collection, including sensitive information. Cyber threats are then potentially more dangerous compared to non-digital processes.

-

Lack of executive support. DT is an extensive process that requires resources and therefore needs strong executive support. However, its technical complexities may sound unfamiliar to operational teams. Without highlighting the practical benefits of these intricate systems, there is a risk of misalignment with executive leadership.

-

Departmental silos. Specified work departments can tend to work in isolation, therefore preventing collaboration. These separate units can pose a challenge as DT looks at a higher company-wide level and wants to integrate all of that data into a single platform.

-

Failure in previous attempts. The fear of recurring failure can demotivate a team to carry on. However, these can be learning opportunities to inform decisions moving forward.

The most prevalent concern of manufacturers about DT is the lack of a clear path. It is a fair consideration, given that an overall strategy can make or break the success of the DT implementation. While manufacturers may be aware of this gap, knowing how or where to start is a whole other challenge.

Not having a clear path is a common problem regardless of the amount of experience that a company has in manufacturing. Identifying this challenge is a reassuring first step to finding a solution and seeking support where needed.

For example, the eBook A Smarter Approach to the Smart Factory lays out a pragmatic approach to achieving smart factory success and offers a solid starting point for taking steps toward DT.

Lack of Understanding of the Digital Transformation Process Leads to Outsourcing

Expertise in manufacturing does not readily translate into being tech-savvy in the wide range of options and features of products in the market. When asked about the upcoming steps in pursuing DT, respondents showed mixed views with relatively high uncertainty. Responses reveal that most manufacturers are still in the learning process of figuring out what comes next.

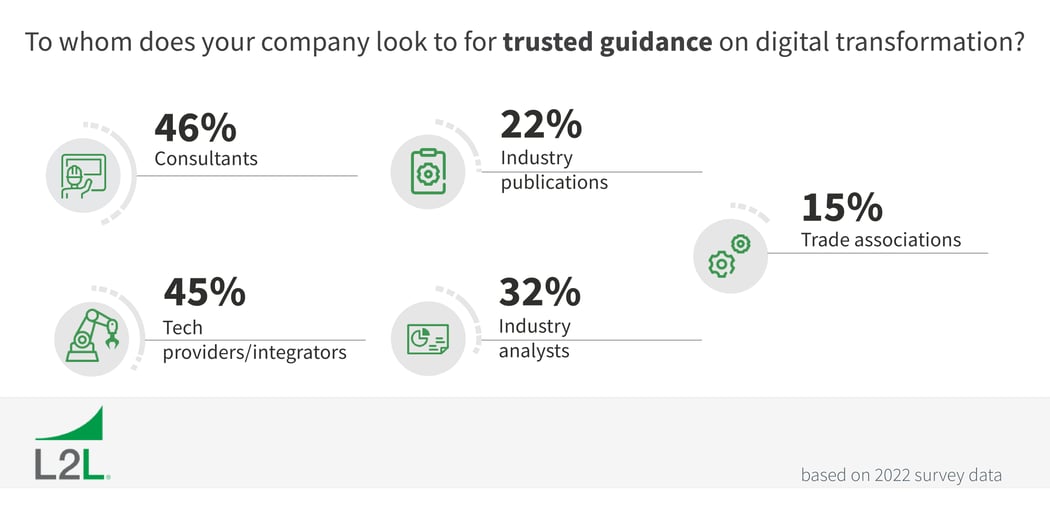

The following logical move after identifying a gap is seeking support. Nearly half of the surveyed manufacturers look to consultants and technology providers for guidance on digitizing their manufacturing process. Not trailing far behind are industry analysts and publications.

Engaging a strategic partner to outsource the DT process offers a broader outlook on the situation. consultants and technology providers bring expertise that is complementary to the existing manufacturing experience of a company. The goal is to match the company's needs and resources with the features of available tools.

What Does Success Look Like for Manufacturers?

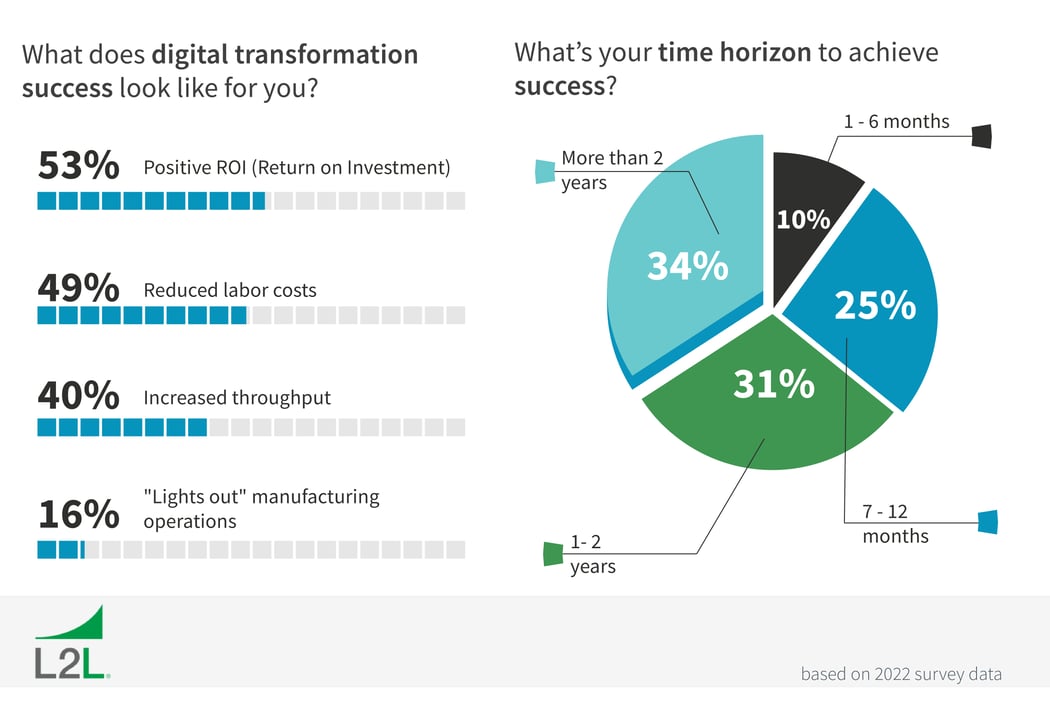

In the context of digital transformation in the manufacturing industry, it is clear that the idea of success closely relates to achieving the expected benefits of DT. Manufacturers want to see a positive ROI, reduced costs, and increased throughput. A good percentage are willing to go as far as implementing a "lights out" manufacturing system.

Eventually, it all goes back to thinking about DT as a part of a broader business objective. The work and effort to develop digital maturity aim to build on the manufacturer's competitive advantage. And in an ever-competitive environment, the speed and precision to transition digitally are crucial for success.

Most manufacturers expect a time horizon spanning more than two years to implement DT.

Real-world data, however, shows that companies can achieve a shorter transition timeline. For instance, attempts to accelerate DT to stay competitive in the middle of difficult times have proven that successful implementations can span just a few months. Depending on the scope of work and the proper support, digitalization is at a closer reach than one might expect.

How L2L Facilitates Your Digital Transformation Journey

L2L can step in at this point since we help manufacturers eliminate the disruptions occurring on their plant floor, which harm their production throughput.

The highly competitive and intricate space that manufacturers operate in can drive a number of operational disruptions that slow production down or bring it to a grinding halt. By eliminating these disruptions, L2L essentially makes plants more efficient, more reliable, and more profitable.

The first step in doing so is identifying the disruptions. The L2L platform digitizes key components of operations, enabling the visibility needed to see a broad set of production disruptors across the plant floor, and to see which issues are the most costly. This enables an accurate prioritization of which of them merit focus and resources, making it possible to realize significant improvement quickly, in a pragmatic and powerful way. Eliminating disruptions translates directly into limiting the negative impacts on people, processes, materials, and machines.

To put it simply: when fully implemented, the L2L Connected Workforce Platform is a continuous improvement engine that coordinates resources, draws attention to key insights, and promotes an efficient manufacturing flow. It fills the gaps that remain from existing enterprise technology and creates a strong foundation for all of your digital transformation initiatives.

To learn more about how L2L can be your foundation for ROI-driven digitalization and smart factory success, visit our Smart Factory Guide.

For a quick way to assess how your level of digitization compares, and what your next steps should be, use our simple Smart Manufacturing Scorecard.

Further Reading

Download our latest research: The State Of Digital Manufacturing in 2023

The State of Digital Transformation in Manufacturing: 2022 Survey